How to Use Integrated GaN Switches for High Efficiency, Cost-Effective Offline Power Supplies

Contributed By DigiKey's North American Editors

2021-07-29

The range of applications for compact 100-watt power supplies continues to increase, from AC-DC chargers and adapters, USB power delivery (PD) chargers, and quick charge (QC) adapters, to LED lighting, white goods, motor drives, smart meters, and industrial systems. For designers of these offline flyback power supplies, the challenge is to ensure robustness and reliability, while at the same time continuing to lower cost, improve efficiency, and reduce the form factor for higher power density.

To address many of these issues, designers can replace silicon (Si) power switches with devices based on wide bandgap (WBG) technologies such as gallium nitride (GaN). Doing so translates directly to improved power supply efficiency and reduced need for heatsinking, enabling higher power density. However, compared to Si, GaN switches are more difficult to drive.

Designers can overcome the issues associated with fast switching speeds, such as stray inductance and capacitance and high-frequency oscillations, but doing so takes added development time and cost. Instead, designers can turn to highly integrated offline flyback switcher ICs with internal GaN power devices.

This article briefly discusses the advantages of GaN and its design challenges. It then introduces three integrated offline flyback switcher IC platforms with internal GaN power switches from Power Integrations and shows how they can be used to produce high-efficiency power converter designs. Complementary MinE-CAP bulk capacitor miniaturization and inrush management ICs are discussed, as well as a useful online design environment.

What is GaN and what’s so good about it?

GaN is a WBG semiconductor material that when compared to Si has low “on” resistance, high breakdown strength, fast switching speeds, and high thermal conductivity. Using GaN in place of Si enables the fabrication of switches that have much lower switching losses during turn-on and turn-off. In addition, GaN devices with equivalent on resistance are much smaller than their Si counterparts. As a result, for a given die size, a GaN power switch has lower combined conduction losses and switching losses (Figure 1).

Figure 1: For a given die size, GaN devices have lower on resistance, leading to lower total losses, compared with Si MOSFETs. (Image source: Power Integrations)

Figure 1: For a given die size, GaN devices have lower on resistance, leading to lower total losses, compared with Si MOSFETs. (Image source: Power Integrations)

While GaN has clear advantages, it can be challenging to design in. For example, due to the extremely fast switching speeds of GaN devices, drive circuit layouts can be very sensitive to stray inductances and capacitances from the pc board and from discrete GaN packages. The fast voltage swings (dv/dt) and high-frequency oscillations that can occur when driving GaN devices create more electromagnetic interference (EMI) that needs to be filtered out to prevent a reduction in converter efficiency. Also, the fast switching of GaN devices makes it difficult to protect them from fault conditions as they can damage the devices faster than protection circuitry can react.

Simplicity without sacrificing performance

Power Integrations has addressed these complexities with its quasi-resonant InnoSwitch3-CP, InnoSwitch3-EP, and InnoSwitch3-Pro PowiGaN switcher ICs (Figure 2). PowiGaN is Power Integrations’ internally developed GaN power switch technology which replaces the traditional silicon transistors on the primary side of the InnoSwitch3 offline flyback switcher ICs. Instead, it integrates primary, secondary, and feedback circuits in a single, surface mount device (SMD) InSOP-24D package. In doing so, the devices reduce driver layout complexity and EMI generation, while also reducing conduction and switching losses, enabling more efficient, lighter, and smaller adapters and chargers, and open frame power supplies.

Using this approach allows power supply designers to focus on power delivery, thermal performance, form factors, and other application considerations without being distracted by the challenging GaN technology.

Figure 2: InnoSwitch3 offline flyback switcher ICs with GaN switches are delivered in the space-saving InSOP-24D package. (Image source: Power Integrations)

Figure 2: InnoSwitch3 offline flyback switcher ICs with GaN switches are delivered in the space-saving InSOP-24D package. (Image source: Power Integrations)

The three InnoSwitch3 families with PowiGaN technology are optimized for specific classes of applications:

- InnoSwitch3-CP is for applications such as battery charging that can benefit from a constant power profile.

- InnoSwitch3‑EP is for open frame AC-DC power supplies in a range of consumer and industrial applications.

- InnoSwitch3-Pro devices include an I²C digital interface for software control of constant voltage (CV) and constant current (CC) setpoints, safety mode options, and exception handling.

The InnoSwitch3 ICs feature quasi-resonant control, up to 95% efficiency across the full load range, support accurate CV, CC, and constant power (CP) outputs to meet a variety of application demands, and include lossless current-sense technology. The latter eliminates the need for external current-sense resistors that reduce efficiency, and which can even exceed the resistance of many GaN switches in discrete designs.

Other key features of the switches include secondary side sensing, a dedicated driver for a synchronous rectification MOSFET, integrated FluxLink inductive coupling feedback connection between the primary side and secondary side controllers with >4,000 volts alternating current (VAC) isolation, compliance with global energy efficiency requirements, low EMI, safety and regulatory compliance (UL1577 and TUV (EN60950 and EN62368) safety-approved), and instantaneous transient response for 100% load steps.

Digitally controllable offline CV/CC QR flyback switcher ICs

Designers of multi-chemistry and multi-protocol battery chargers, adjustable CV and CC LED ballasts, high-efficiency USB PD 3.0+ programmable power supplies (PPS), QC adapters, and similar applications can benefit from using the fully programmable InnoSwitch3-Pro ICs, including the INN3378C, INN3379C, and INN3370C that can be used in AC-DC adapters delivering up to 90 watts, and open frame AC-DC power supplies up to 100 watts (Table 1). These devices are also useful when fine control of output current and voltage adjustment is needed (10 millivolt (mV) and 50 milliampere (mA) steps are supported).

Table 1: InnoSwitch3-Pro ICs are rated for operation with 230 VAC ±15% input and 85 to 265 VAC input. (Table source: Power Integrations)

Table 1: InnoSwitch3-Pro ICs are rated for operation with 230 VAC ±15% input and 85 to 265 VAC input. (Table source: Power Integrations)

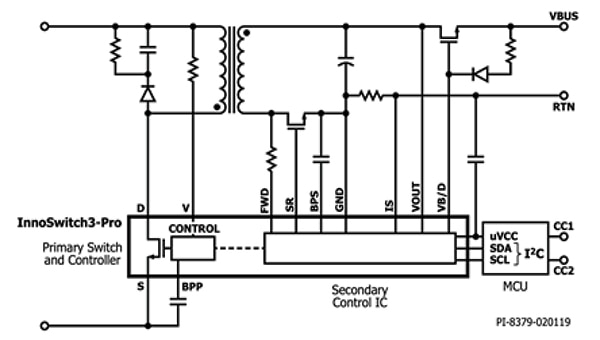

The I²C interface in the InnoSwitch3-Pro devices simplifies the development and production of fully programmable power supplies (Figure 3). It enables dynamic control of output current and voltage. It can be used to configure the power supply, control CV, CC and CP set points, protection settings such as overvoltage and undervoltage thresholds, and handle reporting of faults. The integrated 3.6-volt supply can be used to power an external microcontroller (MCU). Additionally, the <30 milliwatt (mW) no-load power consumption (including the sense line and MCU) meets all global energy efficiency requirements.

Figure 3: The InnoSwitch3-Pro ICs include an I²C interface for full digital control and monitoring, and an integrated 3.6 volt supply (uVCC) to power an external MCU. (Image source: Power Integrations)

Figure 3: The InnoSwitch3-Pro ICs include an I²C interface for full digital control and monitoring, and an integrated 3.6 volt supply (uVCC) to power an external MCU. (Image source: Power Integrations)

Hardware configurable solutions

For applications that don’t require digital programmability or monitoring, Power Integrations offers the InnoSwitch3-CP (Figure 4) and -EP families of hardware configurable solutions. Like the InnoSwitch3-Pro, the InnoSwitch3-CP and InnoSwitch3-EP devices include primary and secondary controllers and reinforced isolation rated for >4000 VAC in a single IC. Protection features include output overvoltage and over-current limiting, AC line overvoltage and undervoltage protection, and over-temperature shutdown. The devices feature high noise immunity, enabling designs that meet EN61000-4 class “A” performance levels.

Figure 4: Shown is the InnoSwitch3-CP in a typical application with the FluxLink inductive coupling feedback connection (dashed line) between the primary and secondary side controllers. (Image source: Power Integrations)

Figure 4: Shown is the InnoSwitch3-CP in a typical application with the FluxLink inductive coupling feedback connection (dashed line) between the primary and secondary side controllers. (Image source: Power Integrations)

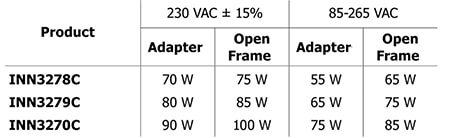

Designers of high-efficiency flyback converters up to 100 watts, for applications such as USB PD, QC adapters, and similar applications, can benefit from using InnoSwitch3-CP devices such as theINN3278C, INN3279C, and INN3270C (Table 2). These QR switcher ICs feature CV and CC modes with constant power profiles, and they support standard combinations of latching and auto-restart. Cable drop compensation is an optional feature.

Table 2: InnoSwitch3-CP family power ratings for adapter and open frame designs. (Table source: Power Integrations)

Table 2: InnoSwitch3-CP family power ratings for adapter and open frame designs. (Table source: Power Integrations)

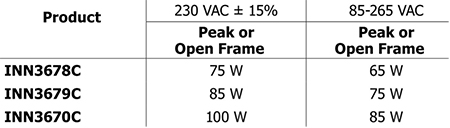

For applications like utility meters, industrial and smart grid power supplies, standby and bias power for white goods, consumer products, and computers that do not use constant power operation, designers can select from the InnoSwitch3-EP devices like the INN3678C, INN3679C, and INN3670C (Table 3).

Table 3: InnoSwitch3-EP ICs are rated for full power at 230 VAC ±15% and derated power with a wide input range of 85 to 265 VAC. (Table source: Power Integrations)

Table 3: InnoSwitch3-EP ICs are rated for full power at 230 VAC ±15% and derated power with a wide input range of 85 to 265 VAC. (Table source: Power Integrations)

InnoSwitch3-EP devices support good multi-output cross-regulation. The output current sense is adjustable with an external resistor, while the CV/CC performance is very accurate and independent of any external components. These QR flyback switcher ICs are available with optional auto-restart output undervoltage protection and can be ordered with standard or peak power delivery options.

Bulk capacitor miniaturization and inrush management

To further reduce component count and enhance performance of AC-DC power supplies, designers using an InnoSwitch3 PowiGaN IC can also use the complementary MinE-CAP bulk capacitor miniaturization and inrush management IC for very high power density designs (Figure 8). MinE-CAP can reduce the volume of input bulk capacitors up to 50%, and it eliminates the need for an inrush current limiting negative temperature coefficient (NTC) thermistor. The use of MinE-CAP also lowers the stresses on the input bridge rectifier and fuse, resulting in improved power supply reliability.

Figure 5: The MinE-CAP bulk capacitor miniaturization and inrush management IC is a natural complement to the InnoSwitch3 offline flyback switcher ICs in high-density AC-DC power supplies. (Image source: Power Integrations)

Figure 5: The MinE-CAP bulk capacitor miniaturization and inrush management IC is a natural complement to the InnoSwitch3 offline flyback switcher ICs in high-density AC-DC power supplies. (Image source: Power Integrations)

Like the InnoSwitch3 ICs, the MinE-CAP leverages the small size and low on resistance of PowiGaN devices to provide increased system performance. MinE-CAP automatically connects and disconnects segments of the bulk capacitor network depending on AC line voltage conditions. This enables designers to use the smallest bulk capacitor (CHV in Figure 5) for high AC line voltage operation while placing most of the energy storage in lower voltage capacitors (CLV) for use under low line conditions. Since lower voltage capacitors are significantly smaller than high voltage ones, the use of MinE-CAP reduces the overall size of the bulk input capacitors with no reduction in efficiency, no increase in output ripple, and without requiring a power transformer redesign.

The use of MinE-CAP reduces the size of power supplies just as effectively as increasing the switching frequency to shrink the transformer size. MinE-CAP solutions use fewer components and eliminate high-frequency design challenges such as increased transformer/clamp dissipation and higher EMI.

Online design tools

Power Integrations also offers PI Expert to speed the design of offline flyback AC-DC power supplies using the InnoSwitch3 line of PowiGaN integrated offline flyback switcher ICs. Built around an automated graphical user interface (GUI), PI Expert uses power supply specifications to automatically generate a power conversion solution. It provides designers with all the details needed to build and test a prototype power converter. Using PI Expert, designers can turn out a complete design in minutes.

Designing with PowiGaN based InnoSwitch3 ICs is the same as using Si-based InnoSwitch3 devices. PI Expert works the same when optimizing switching frequency, EMI filtering, transformer design, biasing, and synchronous rectification for PowiGaN and Si devices. The tool automatically implements any changes needed to accommodate the higher power of PowiGaN-based designs. The tool produces an interactive circuit schematic, complete BOM, detailed electrical parameters, and recommendations for pc board layout. The results also include a complete magnetic design with core size, wire thickness, number of parallel wires, number of turns in each winding, and the winding instructions for mechanical assembly.

Conclusion

Designers need to increase the power density, lower the cost, and reduce the development time of offline 100-watt power supplies for applications ranging from AC-DC chargers and adapters to industrial systems. The use of GaN WGB technology can help, but designing with GaN requires careful attention to board layout and other issues associated with high-speed switching.

As shown, a more integrated approach based on InnoSwitch3 QR flyback switcher ICs allows designers to develop elegant, high-efficiency power converters that provide the performance benefits of GaN switches, while reducing the risks usually associated with adopting a new technology.

Using the InnoSwitch3, combined with Power Integrations’ MinE-CAP inrush current management and bulk capacitor miniaturization IC, as well as the company’s PI Expert online design tools, designers can more quickly implement compact, robust, cost-effective power supplies with low component counts that meet global efficiency standards.

Recommended Reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.