The Fundamentals of IO-Link and How to Use It to Enable the Industrial IoT

Contributed By DigiKey's North American Editors

2020-01-15

Manufacturers and facilities managers are increasingly aware of the potential of the Internet of Things (IoT) and Industrial Internet of Things (IIoT) to lower costs, improve processes and safety, and lead to higher equipment availability and end-product quality. To take advantage of this potential, operations engineers and technicians onsite need a way to efficiently deploy and connect hundreds—if not thousands—of intelligent sensors and actuators to gather data on systems and process elements that weren’t originally designed for two-way communication.

At the same time, and equally challenging, is the need to efficiently integrate current networks of connected devices and systems into IIoT networks to achieve an acceptable level of interoperability across the board with the lowest possible cost and system complexity.

The IO-Link (IEC 61131-9) single-drop digital communication interface standard is a global attempt to solve many of these sensor and actuator connectivity issues. While it’s simple in theory, the challenge is that because it is a relatively new standard, many designers are unfamiliar with what it is and how to use it.

This article introduces IO-Link to operations engineers and technicians looking to properly and quickly implement a sensor network, but who are not intimately familiar with the standard. By way of example, and to help initiate the discussion around IO-Link implementation practicalities, suitable IO-Link system components will be introduced from vendors including STMicroelectronics, Texas Instruments, Carlo Gavazzi, Phoenix Contact, Analog Devices, and Omron.

What is IO-Link?

IO-Link is a digital point-to-point wired (or wireless) serial communications protocol that uses the ubiquitous three wire cable for sensor and actuator connections. It also accounts for devices needing additional power by including the standard five wire interface. It was developed by the IO-Link consortium, and in 2010 it was integrated into the IEC 61131-9 standard for programmable logic controllers (PLCs) as “Single-drop digital communication interface for small sensors and actuators” (SDCI).

The key difference between conventional I/O and IO-Link is that IO-Link is able to transmit four main classes of data:

- Process data: Process data includes analog values and switching states and are sent cyclically—i.e., every communication cycle.

- Value status: Each port has a value status (PortQualifier). The value status indicates whether the process data are valid or invalid. The value status can be transmitted cyclically with the process data.

- Device data: These can be parameters, identification data, and diagnostic information. They are exchanged acyclically and at the request of the IO-Link master. Device data can be written to and also read from the device.

- Events: Events are acyclic and can be error messages (e.g., short-circuit), warnings/maintenance data (e.g., soiling, overheating).

Note that the transmission of device parameters or events occurs independently from the cyclic transmission of process data. These transmissions do not influence or impair each other.

IO-Link does not require special cables and connectors. It instead specifies the use of standard unshielded, three or five conductor cables with a maximum length of 20 meters (m). M5, M8 and M12 circular connectors are standard.

For the three conductor connection type, called Port Class A in the IO-Link nomenclature, one of the three conductors is used for communication, one for power supply to the device electronics, and one as the common reference potential. This connection can provide a maximum current output of 200 milliamps (mA). The spec also calls for a four-pin connector, with the fourth pin used as an additional signal line complying with IEC 61131-2. Its support is optional in both masters and devices.

The five conductor connection mentioned above is called Port Class B and it allows for devices (typically actuators) that need additional power from an independent galvanically isolated 24 volt supply.

One of the special features of IO-Link is its fieldbus neutrality. It allows IO-Link functionality to be connected to just about any fieldbus. Either the standardized mappings in fieldbuses such as Profibus, Profinet, EtherCAT, and Sercos, or manufacturer specific mappings for EtherNet/IP, CANopen, Modbus, CC-Link, and AS-Interface can be used by IO-Link.

This fieldbus neutrality is enabled by the fact that every IO-Link device has an IO device description (IODD) that is independent of the fieldbus or the controller. The IODD contains information about the device, like the manufacturer, model number, serial number, device type, and parameter details.

Configuration elements of an IO-Link system

An IO-Link system comprises and IO-Link master, and IO-Link devices such as sensors and actuators (Figure 1). All IO-Link devices connect to an IO-Link master.

Figure 1: An IO-Link system consists of a controller (outlined in black), an IO-Link master (or multiple masters) connected by simple, standard three or five wire cable connections to IO-Link devices such as sensors and actuators. (Image source: IO-Link Community)

Figure 1: An IO-Link system consists of a controller (outlined in black), an IO-Link master (or multiple masters) connected by simple, standard three or five wire cable connections to IO-Link devices such as sensors and actuators. (Image source: IO-Link Community)

The controller in an IO-Link system is configured by the communications master and the CPU. It executes the user program and I/O is exchanged with the IO-Link master.

The IO-Link Master Unit connects as a slave to the controller over fieldbuses such as EtherCAT, Profibus, or Omron NX bus (Figure 2). This unit performs IO-Link communications with the IO-Link devices.

Figure 2: The IO-Link Master Unit has multiple ports to allow it to connect 1:1 to multiple IO-Link sensors and actuators. (Image source: IO-Link Community)

Figure 2: The IO-Link Master Unit has multiple ports to allow it to connect 1:1 to multiple IO-Link sensors and actuators. (Image source: IO-Link Community)

If an event occurs, the device signals the presence of the event to the master. The master then reads out the event. Error messages are transmitted from the device to the controller or a human-machine interface (HMI) via the IO-Link master. The IO-Link master can also transmit events and statuses on its own behalf. Examples of such events are wire breaks or communication failures.

Each port of an IO-Link master is able to process both binary switching signals and analog values (e.g., 8 bits, 12 bits, 16 bits). Serial IO-Link communication takes place via the same port. Along with easy wiring, additional advantages of IO-Link include automated parameter setting and extensive diagnosis features.

The IO-Link standard enables two bytes of process data to be available per cycle. The transmission between IO-Link master and device takes 400 microseconds (μs) at a speed of 230 kilobaud (kbaud). Users can control the data frame size, so greater process data lengths of up to 32 bytes can also be transmitted at a lower cycle time.

To ensure that the parameter data of a device is not lost when replacing a device, that data can be automatically stored directly in the IO-Link master. If a new, identical, substitution device is connected, the parameters of the previous device are automatically transferred onto the new device.

A good example of master functionality is provided by the STEVAL-IFP016V2 IO-Link communication master transceiver demo board from STMicroelectronics (Figure 3). This has an STMicroelectronics L6360 IO-Link master port that functions as a communication transceiver for multiple I/O devices: it is both IO-Link master port mode and standard I/O mode compliant. This board interfaces to an external microcontroller and demonstrates the capability of the L6360 monolithic IO-Link master as a communication transceiver for multiple I/Os.

Figure 3: The STEVAL-IFP016V2 demo board, with an L6360 IO-Link master port (center), demonstrates the capability of the L6360 monolithic IO-Link master as a communication transceiver for multiple I/Os. (Image source: STMicroelectronics)

Figure 3: The STEVAL-IFP016V2 demo board, with an L6360 IO-Link master port (center), demonstrates the capability of the L6360 monolithic IO-Link master as a communication transceiver for multiple I/Os. (Image source: STMicroelectronics)

Tip: Always ask the demo board manufacturer for Gerber files for their board so that they can be integrated into the system architecture.

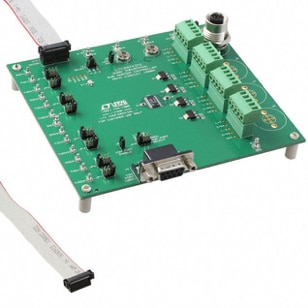

Another example is Analog Devices’ DC1880A demo board, which showcases the LTC2874 quad IO-Link master, hot swap controller, and physical layer interface (PHY). The LTC2874 can also be configured to power higher current serial input/output (SIO) devices in special cases (Figure 4).1

Figure 4: The DC1880A is a demo board for the LTC2874 quad hot swap controller and PHY for an IO-Link master. (Image source: Analog Devices)

Figure 4: The DC1880A is a demo board for the LTC2874 quad hot swap controller and PHY for an IO-Link master. (Image source: Analog Devices)

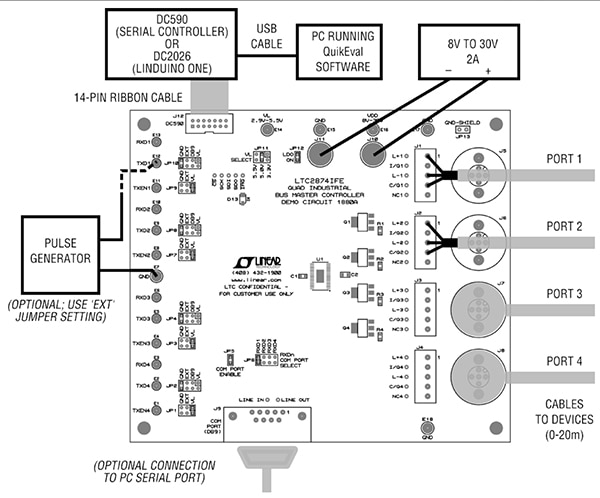

The board operates from an external supply and uses the DC590B USB serial controller board to communicate with the LTC2874 using the SPI protocol (Figure 5). The DC2026C Linduino One isolated Arduino-compatible demo board completes the support software part of the IO-Link system.

Figure 5: To get started with the DC1880A demo board, download the associated evaluation software, connect the DC590B board to the PC, and connect the DC1880A board to the DC590B board. (Image source: Analog Devices)

Figure 5: To get started with the DC1880A demo board, download the associated evaluation software, connect the DC590B board to the PC, and connect the DC1880A board to the DC590B board. (Image source: Analog Devices)

To get started with DC1880A demo board, download the QuickEval software, connect the DC590B board to the PC using a standard USB A/B cable, and connect the DC1880A board to the DC590B board using the 14 conductor ribbon cable supplied with the DC590B board. Jumpers on the DC1880A board are used to set the different voltages to power the Logic Supply (VL) voltage pins to the DC590 board and the DC1880A boards. Power-up must be done in stages. Before connecting the input power make sure it’s under 40 volts, and that the supply is turned off before connecting.

IO-Link power-up operation

When an IO-Link master such as the LTC2874 powers up, it interrogates each connected device to determine the proper operational mode for the device. This allows for a mixture of legacy and IO-Link enabled devices to operate seamlessly in the same system. For example, the ports of the LTC2874 are set as one standard I/O (SIO) port (Port 4) with L+ hot swap, and three high current (SIO+) ports (Figure 6).

Figure 6: The LTC2874 quad IO-Link master configured as three high current SIO ports (SIO+) and one normal SIO current port (Port 4) with L+ hot swap. (Image source: Analog Devices)

Figure 6: The LTC2874 quad IO-Link master configured as three high current SIO ports (SIO+) and one normal SIO current port (Port 4) with L+ hot swap. (Image source: Analog Devices)

Arbitrarily large currents—for LTC2874 operation in SIO+ mode—may be obtained by repurposing the hot swap channels as higher current SIO drivers. The LTC2874 has rated communication or signaling (CQ) current of 110 mA. Higher currents of up to 440 mA can be attained by paralleling SIO channels. Note that this exceeds IO-Link specs of a maximum current output of 200 mA. If a designer chooses to exceed 200 mA, IO-Link features and capabilities from the LTC2874 will still be maintained, but the standard requirements will be violated.

For an IO-Link interface for industrial point-to-point communication, the Texas Instruments SN65HVD101EVM IO-Link interface eval board for the SN65HVD101 and SN65HVD102 transceivers helps designers evaluate the device performance, supporting the fast development and analysis of these two IO-Link PHY devices.

The SN65HVD101 and SN65HV2102 IO-Link PHYs implement the IO-Link interface for industrial point-to-point communication. When the devices are connected to an IO-Link master, they will respond to communication initiated by the master. These PHY devices will exchange data with the master node, acting as a complete physical layer for bi-directional communication.

Fully packaged and deployable IO-Link masters include the DIN-rail mountable 1072839 IOL MA8 EIP DI8 eight-channel IO-Link master from Phoenix Contact (Figure 7).

Figure 7: The 1072839 eight-channel IO-Link master from Phoenix Contact mounts on a DIN rail and forms an IO-Link to EtherNet/IP and Modbus TCP gateway. (Image source: Phoenix Contact)

Figure 7: The 1072839 eight-channel IO-Link master from Phoenix Contact mounts on a DIN rail and forms an IO-Link to EtherNet/IP and Modbus TCP gateway. (Image source: Phoenix Contact)

The IOL MA8 EIP DI8 forms a complete IO-Link to EtherNet/IP and Modbus TCP gateway and can connect up to eight IO-Link sensors with web-based management (Figure 8). It has two switch-classified Ethernet ports, status LEDs and easy-to-use connectors for power and IO-Link ports.

Figure 8: A web interface to the IO-Link master provides full control and diagnostics of all connected IO-Link devices. (Image source: Phoenix Contact)

Figure 8: A web interface to the IO-Link master provides full control and diagnostics of all connected IO-Link devices. (Image source: Phoenix Contact)

Full access to all IO-Link devices is provided via the web interface. For example, to access the diagnostics pages on the web interface, the user just needs to login to the IOL MA8 EIP DI8, click the “Diagnostics” tab, and then click the desired subtab. To show the “IO-Link Diagnostics” page shown in Figure 8, the user simply clicks the “IO-Link” subtab.

IO-Link sensors

With IO-Link, designers can efficiently deliver data from the sensor directly into a control system. The flexibility of IO-Link-capable sensors allows machines to operate more effectively by providing the controller with diagnostics. In addition to their basic sensing function, such as detecting items on a conveyor belt, the right sensors, placed strategically, can provide detailed and accurate machine health status. This is used in the IIoT to improve equipment uptime and overall productivity by predicting failures before they happen.

Sensor options for IO-Link are plentiful. For example, Carlo Gavazzi offers a particularly rugged capacitive proximity sensor, the CA18CAN12BPA2IO. The sensor has a response time of under 10 milliseconds (ms) and uses the company’s fourth generation TripleshieldTM technology to provide improved immunity to electromagnetic interference (EMI), particularly to frequency drives, and to improve its immunity to humidity and dust (Figure 9).

Figure 9: The CA18CAN12BPA2IO capacitive proximity sensor from Carlo Gavazzi is a new generation of CA18CA series of IO sensors that provides improved immunity to EMI, especially to frequency drives, as well as improved immunity to humidity and dust. (Image source: Carlo Gavazzi)

Figure 9: The CA18CAN12BPA2IO capacitive proximity sensor from Carlo Gavazzi is a new generation of CA18CA series of IO sensors that provides improved immunity to EMI, especially to frequency drives, as well as improved immunity to humidity and dust. (Image source: Carlo Gavazzi)

The sensor meets IP69K testing according to DIN 40050-9 for high pressure, high temperature wash down applications. It comes with a 2 meter (m) cable length and has a sensing range of 2 to 10 mm (flush mounted) or 3 to 15 mm (non-flush).

Adjustable parameters via the IO-Link interface are:

- Sensing distance and hysteresis

- Sensing modes: single point or two point or window mode

- Timer functions like: On-delay, Off delay, One shot leading edge or trailing edge

- Logic functions such as: AND, OR, X-OR, and SR-FF

- External input

- Logging functions: Maximum temperatures, minimum temperatures, operating hours, operating cycles, power cycles, minutes above maximum temperature, and minutes below minimum temperature, among others

It’s worth noting that these sensors, like all IO-Link sensors, act like standard sensors when not interfaced to an IO-Link enabled control system. As a result, users can stock the same sensors for standard I/O applications and IO-Link applications, thereby simplifying the selection process and reducing inventory costs.

If a PC or a laptop is not available, the Carlo Gavazzi SCTL55 IO-Link Smart Configurator is a portable, self-powered device that can modify and optimize sensor parameters and use available data to improve processes and assist in predictive maintenance (Figure 10).

Figure 10: The Carlo Gavazzi Smart Configurator for IO-Link sensors can access sensor data and manage its parameters. (Image source: Carlo Gavazzi)

Figure 10: The Carlo Gavazzi Smart Configurator for IO-Link sensors can access sensor data and manage its parameters. (Image source: Carlo Gavazzi)

Through a 5.5 inch high-definition touchscreen display and dedicated apps, users of the smart configurator can access advanced diagnostics and troubleshoot, as well as view operating hours, number of detections, operating cycles, and alarms.

Upgrading legacy automated production systems with IO-Link

The IO-Link standard states that upgrading legacy systems with existing fieldbus structures can be achieved as long as the system map of IO-Link has already been implemented for the bus system in question. An expansion of existing bus systems is possible. To exchange data between an IO‐Link device and a PLC, the IO‐Link master maps the IO‐Link data to the fieldbus used.

Non-IO-Link capable sensors can be connected to an IO-Link master if they have standard PNP outputs or push-pull outputs. No special IO-Link cables or connectors are required.

Conclusion

With the rapid adoption of the IIoT, designers need a fast and standardized means of deploying and connecting intelligent sensors and actuators. IO-Link brings this standardization with an easy-to-use digital interface.

As shown, there are many off-the-shelf solutions to help designers quickly understand, evaluate, and efficiently deploy IO-Link devices. In doing so, they can fulfill the promise of IIoT improved processes, more efficient production, enhanced safety, and reduced downtime.

Reference

- Quad IO-Link master with higher current SIO channels ADI Power by Linear, Design Note 566, Eric Benedict - November 29, 2017

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.